Products Catalogs

Surface Well Testing

- Flowhead - Surface Test Tree

- Surface Safety Valve

- Emergency Shut Down

- Chemical Injection Pump

- Choke Manifold

- Automatic Choke Manifold

- Choke Bean

- Adjustable Choke

- Cage and Sleeve Choke

- Hydraulic Choke Valve

- Electric actuated Choke Valve

- Orifice Plate Choke Valve

- PosItive Choke

- Data Header

- Diverter Manifold

- Dual Pot Sand Filter

- Cyclonic Sand Separator

- Cyclonic Wellhead Desander

- 3 Phase Separator

- Vertical Surge Tank

- Steam Heat Exchanger

- Crude Oil Transfer Pump

- High Pressure Flexible Hose

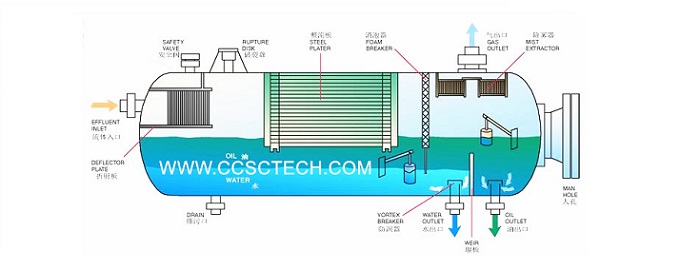

3 Phase Separator - Test Separator

3 Phase Separator - Test Separator is a horizontal steel pressure vessel designed to efficiently separate well effluent into three phases - water, oil, gas, for production well testing and frac flowback operation.

3 phast separator typically consists of a vessel, an oil flow-measuring system with dual meters, a flow-measuring system that utilizes turbine meters, and eletronic gas flow measurement systems with several sampling points, and two relief valves to protect the vessel against overpressure. To provide accurate measurements, the 3 phase separator is fitted with pneumatic regulators that maintain a constant pressure and a constant liquid level inside the vessel by control valves on the oil and gas outlets.

3 phase separator - test separator is fitted with a deflector plate, coalescing plates, a foam breaker, a vortex breaker, a weir plate, and a mist extractor. These components reduce the risk of carryover (liquid in gas line) and carry under (gas in liquid line) that would affect the flow rate measurement accuracy.

The typical sizes of 3 phase separator are 42" x 10' 1440psi, 48" x 12' 1440psi, the most popular brands for the key components are: Barton Recorder, Fisher Level Controller, Daniels Gas Orifice Meter, Balon Ball Valves, etc. we accpet all brands over the worlds based on clients requirement.